ISOLAR Kompass

INTRODUCTION

The manufacturing of flat glass products as well as multi-pane insulating glass is now a highly automated technological process, which has developed over many years into a complex multi-stage production process. The wide range of innovative multi-pane insulating glass products requires a certain amount of flexibility in the production facilities of insulating glass manufacturers. Even with the most modern and sophisticated production facilities, it is still not possible to completely eliminate production-related tolerances in the end product. These tolerances must be taken into account by the downstream trades, like for instance, façade or window installers. Permissible deviations, as defined in the various standards, are in principle interpreted in such a way that the technical function and lifespan of the product are not affected.

Clients and contractors often have different views on permissible tolerances when it comes to the visual aspects of the end product. To address this fact, in recent years, tolerance specifications have been developed according to which both the finished insulating glass and the semi-finished products have be evaluated during production.

Normative Bases

Tolerances of the individual products are defined in many standards. This means that tolerances of the finished product, the insulating glass, may also be regulated in standards for intermediate products.

The most important product standards in the glass industry are certainly:

- EN 572 “Glass in building – Basic soda-lime silicate glass products”

- EN 12150 “Glass in building – Thermally toughened soda lime silicate safety glass”

- EN 14179 „Glass in building – Glass in building – Heat soaked thermally toughened soda lime silicate safety glass“.

- EN 1863 “Glass in building – Heat strengthened soda lime silicate glass”

- EN 14449 “Glass in building – Laminated glass and laminated safety glass”

- EN 1096 “Glass in building – Coated glass”

- EN 1279 “Glass in building – Insulating glass units”

- DIN 1249-11 “Flat glass in building – Part 11: Glass edges – terms and definitions, characteristics of edge types and finishes”

This multitude of standards often presents difficulties in their practical application and sometimes allows for a degree of latitude in their interpretation. Glass products that are traded in the European area and comply with a harmonized standard require CE marking. With this marking, the manufacturer confirms that the glass products comply with the quality defined in the standard. This provides both the customer and the contractor with the legal certainty they need when working with tolerances. In addition to the legally binding product standards, there are information sheets and data sheets as well as guidelines from various trade associations (BF, VFF, ...), which are well established on the market. Their applicability should be assessed individually by the contracting parties.

TECHNICAL TOLERANCES

Technical tolerances are deviations within which the glass products can be produced in terms of dimensions, thickness, offset, etc., without affecting the function, load-bearing capacity or lifespan of the product. These are usually not visible to the end customer. The assessment is done using the measuring equipment and objective methods defined in the relevant standards.

Thickness tolerances at the edge seal

| Glazing | Pane | IGU-Thickness Tolerance |

| Double- glazing |

all panes are stress-relieved float glass | ± 1,0 mm |

| at least 1 pane LSG, ornamental glass or TSG/HSG | ± 1,5 mm | |

|

Triple- glazing |

all panes are stress-relieved float glass | ± 1,4 mm |

| at least 1 pane LSG, ornamental glass or TSG/HSG | + 2,8 mm / -1,4 mm |

Offset for rectangles

| Double/triple glazing | Tolerances for W+H | Offset |

| all panes ≤ 6 mm and (W+H) ≤ 2.000 mm |

± 2 mm | ≤ 2 mm |

| 6 mm < thickest pane ≤ 12 mm or 2.000 mm < (W or H) ≤ 3.500 mm |

± 3 mm | ≤ 3 mm |

| 3.500 mm < (W or H) ≤ 5.000 mm and the thickest pane ≤ 12 mm |

± 4 mm | ≤ 4 mm |

| 1 pane > 12 mm or (W or H) > 5.000 mm |

± 5 mm | ≤ 5 mm |

| The thickness is nominal thickness. | ||

VISUAL AND OPTICAL TOLERANCES

Visual and optical tolerances refer to the perception of the surfaces or the transparency of different glass products. These include optical distortions in the glass surface, the colour impression, the dimensional accuracy of patterns, visual imperfections that affect the transparency of glass products, and damage to the surface such as scratches. These characteristics are obvious to the end customer and can accordingly often lead to discussions. It needs to be mentioned here that the visual quality of insulating glass products has been defined in DIN EN 1279-1 since 2018, and since then a binding minimum requirement also exists. The quality is assessed using measuring equipment as well as defined methods in accordance with this standard. However, depending on lighting conditions and the viewer’ perception, there are always differences of opinion on this subject.

Punctiform defects

| Zone | Defect size (excluding halo) Ø in mm | Pane size S in m² | |||

| S ≤1 | 1 < S ≤ 2 | 2 < S ≤ 3 | S < 3 | ||

| R | all sizes | no restriction | |||

| E | Ø ≤ 1 | acceptable if less than 3 in each area with Ø ≤ 20 cm | |||

| 1 < Ø ≤ 3 | 4 | 1 per m of edge length | |||

| Ø > 3 |

not acceptable | ||||

| M | Ø ≤ 1 | acceptable if less than 3 in each area with Ø ≤ 20 cm | |||

| 1< Ø ≤ 2 | 2 | 3 | 5 | 5+2/m² | |

| Ø > 2 | not acceptable | ||||

Permissible number of punctiform defects (EN 1279-1:2018-10)

Residues

| Zone | Dimension + Type Ø in mm | Pane size S in m² | |

| S ≤1 | 1 < S | ||

| R | all | no restriction | |

| E | spot Ø ≤ 1 | no restriction | |

| spot of 1 mm < Ø ≤ 3 |

4 | 1 per meter edge length | |

| stain Ø ≤ 17 | 1 | ||

| spot Ø > 3 and stain Ø > 17 | maximum 1 | ||

| M | spot Ø ≤ 1 | maximum 3 in each area with Ø ≤ 20 cm | |

| spot 1 < Ø ≤ 3 stain |

maximum 2 in each area with Ø ≤ 20 cm | ||

| spot Ø > 3 + stain Ø > 17 | not acceptable | ||

Permissible number of spot and stain residues (EN 1279-1:2018-10)

Linear / longitudinal defects

| Zone | Individual lengths mm | Individual lengths cumulated mm |

| R | no restriction | |

| E | ≤ 30 | ≤ 90 |

| M | ≤ 15 | ≤ 45 |

Permissible number of linear/longitudinal defects (DIN 1279-1:2018-10) Very fine scratches are permissible provided they do not form a build-up.

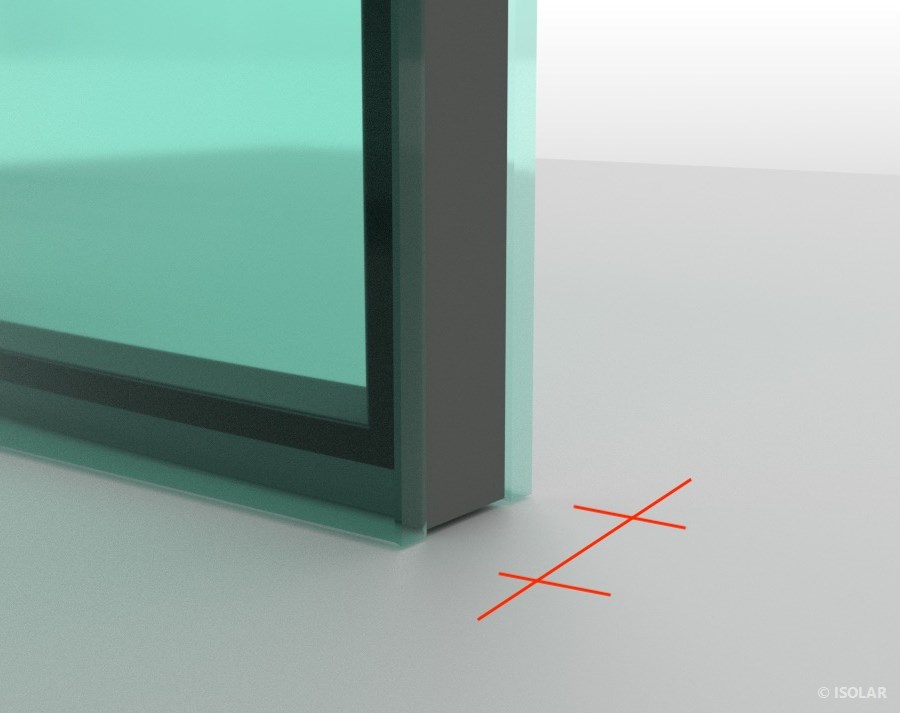

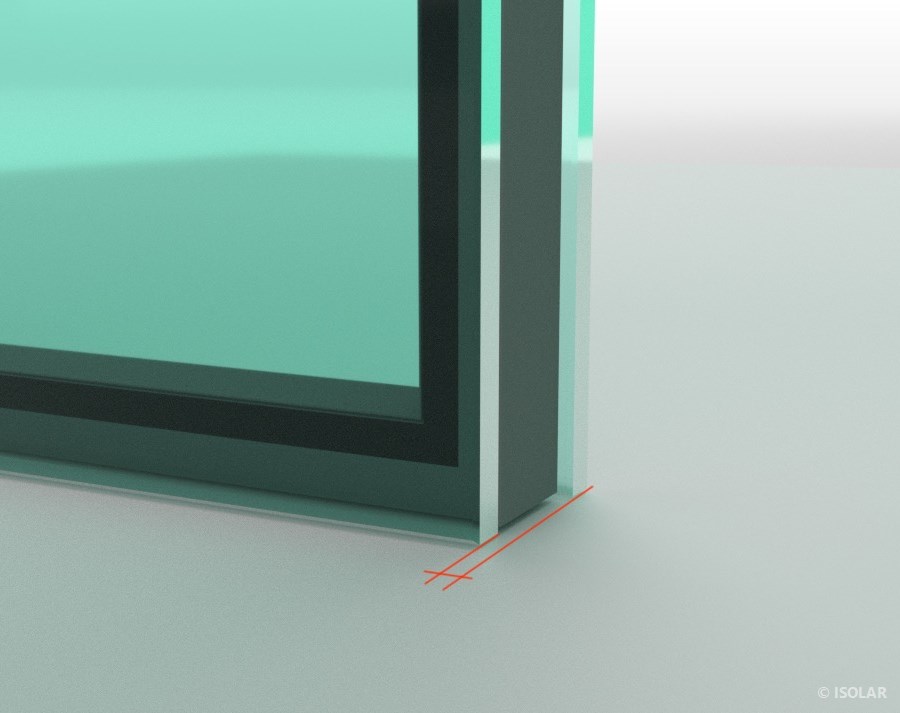

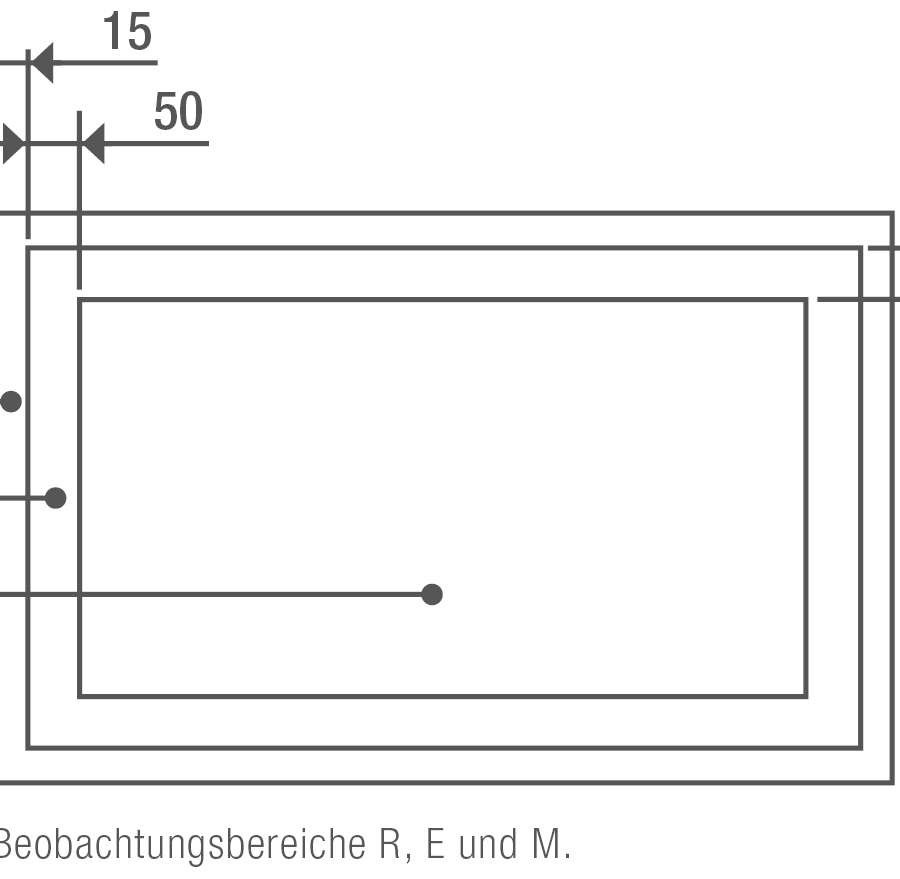

R = Rabbet zone: Zone of 15 mm, which is usually covered by the frame or corresponds to the edge seal in the case of a frameless edge.

E = Edge zone: Edge zone of the visible surface, with a width of 50 mm

M = Main zone

PHYSICAL CONDITIONS

Some phenomena are described in the following, which can be perceived under certain circumstances, but cannot be prevented due to physical conditions.

Anisotropies

Anisotropies refer to an interfering effect in mostly thermally toughened glass (TSG/HSG). The heat-treatment process introduces different stresses into the glass, causing birefringence in the glass. In polarized light, these birefringences are perceived as disturbing optical effects. Usually, anisotropies are perceived as grey rings, stripes, or even leopard patterns. As the glass thickness increases, this effect becomes even more pronounced. Polarized light is present in normal daylight, hence this effect can never be completely eliminated.

Interferences

In the case of insulating glass made of float glass, interference can occur in the form of spectral colours. Optical interferences are superposition phenomena of two or more light waves when they meet at one point. They appear as more or less intense coloured zones that change when pressure is applied to the pane. This physical effect is reinforced by the plane parallelism of the glass surfaces, which ensures distortion-free transparent view. Interference phenomena occur randomly and cannot be influenced.

Condensate on the external surface

Especially in autumn and spring, condensate can be observed on the outer surface of a glazing in the morning. The outer surface of the thermal insulation glass, like all other surfaces, is in a „radiation exchange“ with the environment. The external pane emits heat and thus becomes colder on the outer side. A clear, „cold“ night sky has an extremely low „radiation temperature“ of up to -50°C. How much the outer side of the thermal-insulating glass will cool down, however, also depends on how quickly it is being supplied with a „replenishment“ of heat. Thermal insulating glass prevents this replenishment. The lower the Ug-value of the glazing, the less the heat transferred to the external panes. Condensation on the external panes occurs when they are colder than the ambient outdoor air, and this air is saturated with moisture.

Wettability

The wettability of the glass surface on the outer sides of the insulating glass may vary, for example, due to impressions from rollers, fingers, labels, paper grains, vacuum cups, sealant residues, smoothing agents or lubricants, or environmental influences. In damp glass surfaces due to condensation, rain or cleaning water, the difference in wettability may become visible.

Double pane effect

The system of a multi-pane insulating glass unit prevents pressure equalization of the gas or air volume sealed between the panes with the ambient air. In case of changes in climatic conditions—compared to the conditions at the time of production of the MIG—the general gas laws apply to the gas or air in the inter-pane space. The behaviour of the multi-pane insulating glass is influenced by the ambient temperatures, solar radiation, weather conditions (air pressure) and the installation height compared to the height during production. The consequences of this

may be changes in pressure in the inter-pane space and deformations on the glass surface. The use of panes having an increased absorption of solar radiation, as well as large spaces between panes, can increase this effect. In the case of insulating glass units having an asymmetrical glass structure (e.g. sound-insulating glass units, attack-resistant glazing), this can lead to extreme loads on the insulating glass unit if the pane formats are unfavourable. These influences are system-related and cannot be avoided.